Rewiring Progress on the Z650/KZ650

Well some forward progress was made on the wiring. I took a couple of days of work to start making real progress. Unfortunately the British weather was well British which slowed things down.

I got out the tarp again to make some form of shelter to work under.

First job was to get the Dyna Coils in place. I had to order some nylon spacers from ebay and sand them down to the right size, but they now fit perfectly.

I also managed to get the battery and M-Unit mounting into place to make sure it would fit. Luckily it did!

Next up I fitted the Dyna S ignition. I’ve not set it up fully yet, but it’s in place.

Other jobs included a new mounting point for a new brake reservoir as the previous one was leaking. I knocked this up in aluminium, Also I had fitted the new switches from Highway dirtybikes. These mount directly onto the brake levers. Sadly the left one doesn’t fit so I had to use a different switch setup from the previous switch setup. It’s still cool looking but I wanted two identical ones instead of similar ones.

I’ve broken the back of the main rewiring, it’s just the final fitting into place of the main loom. I am fed up of seeing and working on cables and connectors now, but it will be worth it.

With a lot of the loom work I tried to merge things together to simplify things and make routes to the main loom easier. Such as this section of front indicators/horn and brake switch.

I’ve had a play with the M-Unit and it’s a great bit of kit.

My final completed job was to make a mounting point for the Motogadget M-Lock. I’ve put it down the side so I can easily get to it. It may move when I finally decide what to do with the side panels. As I think a hidden setup would be best.

Using the key is awesome, I need to get the glass vial fitted to my glove asap.

Video:

Not going to get more done this weekend, but hopefully I will get the final wiring done soon as I want to ride it!!

Shorai Battery box

A quickish update. I’m still waiting on parts to start the rewire. I’m hoping my birthday tomorrow brings some shiny treats for the bike….

The Shorai Battery arrived and I was blown away by it’s size and weight.

New vs Old

Next to the m-unit it also looks so tiny.

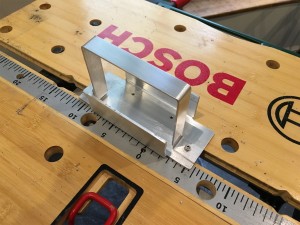

In the meantime I got to work building the battery mounting box. I’m fabricating this out of sheet aluminium. After a couple of sketch drawings I got to work using the bending brake.

A quick test fit.

Next I made the attachment strap out of aluminium as well.

Looks like this should work. I need some longer mounting bolts and some sheet rubber for protecting the battery from the metal, but it’s a start.

Next job will be to drill the holes into the frame for the battery box to mount to. I’m not looking forward to that bit!

Z650 Update and Rewire

So it was about time I updated this project log. I’ve ridden the bike a few times, but I’ve been suffering constant electrical gremlins. I tried replacing the regulator with a Shindengen SH775 ,but that didn’t fix things. As the weather has been foul I’ve not had a chance to do much work on the bike.

For some time now I’ve wanted to do a complete rewire so finally I said sod it and got started. First off I wanted to do it properly and easily so my first purchase was a Motogadget M-Unit

It’s an amazing bit of kit, it makes life much easier for the rewire. To go with it I’ve order lots more kit that is arriving shortly I hope. In the mean time I started removing the old crap wiring.

The bike looks much cleaner with out all that rubbish hehe

When the rest of the kit arrives I can start planning the next phase. Here’s some of my shopping list:

Dyna S complete coils/ignition kit

Motogadget M-Unit

Motogadget M-Lock

Shorai Lithium Battery

New Spark plugs

Loads of wiring bits.

Uni Clamp On Air filters

Starter Relay

Picture of my KZ650 so far.

I need to keep working at it until it’s done. However here it is at the moment.

Carbs fixed but now something new

So I promised an update. Well Tim worked his magic on the carbs and timing. He got it so the bike stopped surging at mid revs and re-jetted so that the power was actually smooth line as the revs increased. Test riding it round the lanes and it was transformed into an amazing ride.

However as with this whole project my luck sucks, I rode in the center of town feeling very happy however on my trip the bike completely cut out with no warning. I managed to get it restarted, but the same thing happened three more times in less than a mile. I managed to get to my destination, but I was pissed off. Interestingly when I started the bike to go home it worked fine all the way home.

Once home I checked things through and with discussions with Tim, I think there is a dodgy connection to the coils. I will be checking the wiring through and changing old dodgy connectors.

I took a couple of pics of the shop

My bike hiding amongst many others. So many spares in this corner.

Some drag bikes

Another job I did before the trip to Tim’s was to sort two things on the rear of the bike.

1. A slow puncture

2. Replace the rear disc.

I managed to do both of these at the same time.

Now I’m back from holiday I can attack the wiring. I saw a camo Z650 when I was in the Lake District too.

Mudguard fitted & carb woes

Quick pre MOT update and mudguard pics.

I managed to create a mount for the triumph mudguard using aluminium pipe bent to shape and attached with P-clips. I had no idea whether it would work or not when I started. First I used the rear tire as a bending guide as it’s about the width that I needed. This gave me the front bracket which I attached to the mudguard as a test.

That worked really well so I set about making the second bracket for the rear.

What I had failed to think about was how to get the brackets and mudguard into place. I had hoped to leave the brackets attached to the mudguard and slide them on, but that was never going to work. So i had a very fiddly time trying to mount the brackets to the mudguard once they were in place. With a lot of swearing and dropping nuts I got there.

I am so delighted in how it turned out. I never expected it to work so well.

Next it was time to refuel the tank and fire it up. This is where the headache started. The bike started ok, but sounded odd, I realised that it was pissing fuel out from somewhere. Not good. I also realised that one of the exhaust headers was cold not hot. Also not good.

I rapidly realised that there was probably a carb issue. I’ve avoided touching these so far as I don’t want to cause more issues than I fix, but needs must. I took them off the bike which was much easier than I was expecting. Thankfully I didn’t need to remove the tank either.

I found some blockages in the carb that I thought was the problem and managed to clean them out. I’ve just put them back in and it seems to have sorted the issue out. Certainly it sounds better and is no longer pissing out fuel which is nice!

A job for this winter is a proper carb clean inside and out.

Brakes and other jobs

I’m so close the end of this….

I’ve made a chunk of progress though it doesn’t all show. The main jobs left to do from last time was sorting the wheel placement and fitment. I then also need to fit the brake calipers.

1. Front axle

I had the axle machined down to the correct length. This meant I could finally test fit the wheel and get the correct spacings

2. Front axle spacers.

The local engineering shop also made up two more spacers for me, once I had worked out what size wheel spacers I needed. I got them to machine down the existing spacer as it was quicker for them. They then created the second one.

3. I picked up some new caliper bolts as the calipers didn’t come with any. This allowed me to fit the calipers and see if it would even work!

4. The original petcock was on it’s way out so I tried to find a suitable replacement. After much research it appeared a Suzuki GS450 one would work, so I ordered one. It turns out it will fit the tank perfectly, but you cannot get it the tank back on the bike! In then end I just put the petcock in with the tank in place. This creates future headaches when removing the tank, but it will have to do.

5. Disc spacers.

With the axle and wheel spacers in place I could finally work out what to do with the discs. As they were touching one side of the brake pads on each caliper. It was around 1.5mm out. I tried to find some suitable disc spacers, but couldn’t find any. In the end I just made my own. In the end they worked perfectly and didn’t take me too long to make.

6. Brake hoses

With the fitment of the brakes I could finally get the brake caliper hoses ordered. I went with some nice Venhill ones like I had used before.

7. Mudguard mounts

I’ve not finished this yet, but after various attempts I think I’ve got the design sorted. It uses some round 6mm aluminium, I bent it to shape around the rear tire to get the perfect bend. I tried to hammer out mountings, but found it far to hard to be perfect. So now I am using some little brackets that I’m waiting to arrive. The pics give you an idea where it’s heading.

8. Speed sensor

The final job I’ve done was to find a place to mount the new magnetic speed sensor. In the end I’ve used a longer cinch bolt on the bottom or the forks. On the extra end section I’ve mounted the Koso speed sensor using the p clip to get it in the perfect place, I then routed the cable using the brake hose as a path for neatness.

GSXR 600 Forks fitted

Well more forward progress towards the getting it back on the road. I had both the bottom yokes and front axle machined to fit the new GSXR 600 forks. They also made up a spacer to fit the larger axle hole in the forks.

I could then try my first test fit of the forks to see if they would work

I then tried to fit the brakes and wheel and hit a major issue. The brakes wouldn’t go on! After 10mins of panic I realised I got the forks on back to front! What a bloody idiot. Anyway I swap the forks round.

The axle is correct in the diameter, but too long, but the wheel fits in place and the axle works! I have taken it back to the machinist to get it down to the correct length.

I have a few more issues to now over come.

1. The original speed sensor will not fit so that has to go.

2. I will need axle spacers or the correct size to make sure the wheel stays in place.

3. Both front discs touch one side of the pads

These are relatively easy to over come.

1. The Koso DB-01R I have has a magnet sensor option which I can pick up locally tomorrow.

2. These will be hard to measure as the wheels are not identical either side, but once measured I can get some knocked up.

3. This is harder, my first reaction was to think about some washers behind the disc, but that seems like a terrible idea. So what I will do is make some spacers out of sheet alumnium that cover the whole of the contact patch. I’m waiting for the axle spacers and brake bolts to turn up before I start these. I’m thinking of something like the picture below.

I have also broken two things when putting everything back in place. I broke the starter button cable which is very annoying. I also found the mounting bracket for the Koso speedo was snapped off. I’ve managed to glue that back in place.

I should have the axle back later this week so I can get some more work done this weekend.

Old forks new Forks

Well as seems to be the case with this project. It’s been two steps forward one step backwards. I’m losing the will with it at the moment.

When last I did an update I was awaiting tools so that I could remove the front axle and therefore the front forks. I managed to do this in the end and took them into the garage to have the seals redone. However after discussing it with them, they noticed some rather bad pitting on the inside of the forks hidden from view. They recommended that they would need to be rechromed sometime soon. As a short term solution to get me on the road I asked them to replace the seals anyway and I would look at more long term solutions.

However they simply couldn’t get the forks to come apart, they tried everything they could including using a blow torch to heat them up. So we had to abandon them. I have to give the garage thumbs up as they must of spent hours on them, but didn’t charge me a single penny.

That gave me a big headache, I saw little point in spending a fortune on similar ZXR400 forks as they would also be nearly 20years old and need work soon. I headed to the web to see if I could find a suitable alternative option.

What I was hoping for was some forks of the same diameter as the ZXR400’s but newer and more modern. This proved to be fruitless. I could just do a whole front end swap, but I wanted to not spend a small fortune on this! Eventually I settled on some forks that I think will work, I had to do a ton of research and all kinds of bikes to find out what would be best. I even had to use a spreadsheet :sick:

The ZXR400 forks are the following dimensions

Length 745mm

Top Yoke Diameter 50mm

Bottom Yoke Diameter 52mm

Standard calipers

310mm Discs

The closest match I could find we GSXR 600 K6 forks, they match for everything apart from the brakes, bottom yoke, mudguard and axle….. Groan :sick:

Next I have to get the old forks back of the bike as I put them back on so I could use the ladder!

I then set about removing the yokes as well. I thought it would be a nightmare, but it wasn’t too bad

Next week I will be taking the axle in to be machined and a spacer created. As it’s a pretty close match. The yokes will be machined out from 52mm to 53mm. The light brackets will also need to be changed, but I’ve already sorted them out with some small rubber pieces to act as spacers.

I also had to find a new mudguard which was particular annoying as I’ve only just had this one made for me! I wanted something more similar to this bikes one

I managed to find a small triumph mudguard. I will need to make a custom mount for it

So there we go, another depressing update, but I can see some blue sky in the future at least now.

More progress on the Z650

So an update on progress which has been up and down.

I didn’t fancy trying to fit the shock and new linkage myself so I booked it in at the local motorbike shop 100m away. They fitted it and it went well apart from the top linkage bolt size. The bolt is too small for the shock and due to the way the frame is braced they couldn’t just make a bigger hole. It looks ace in place though!

I went to an amazing local engineering shop to get them to make up a reducer for me. It was pure old school engineering no cnc stuff that I could see.

I then put the bike through another MOT which is failed again. ARRRGH! This time it was the front shocks which were misting slightly before are now leaking badly. Also the rear lights were an issue as the number plate light was too bright and caused problems.

So I started taking the front end apart to remove the shocks

Which is where I got stuck as I don’t have the correct tool to remove the front axle. I’ve got one side but not the other. I’ve ordered the tool which should be here this week.

I decided this was a good opportunity to move the key location so that I can tidy up the speedo area. I created a bracket to mount the key under the tank. Which I thought came out nice in the end.

Next I wanted to remove the old key hole to allow me to make a new speedo bracket.

It all is much tidier now and closer to my face.

Next up on the jobs I could do before tools arrive was to clean up the front brakes. As fork oil had leaked onto the pads and discs. I thought about cleaning the pads off, but decided it was far safer to replace them.

Finally I realised that the number plate light is not a legal requirement in the uk so it could go. This meant I could redo the rear bracket and make it simpler.

So I’m stuck waiting for tools before I can finally get it on the road. Fingers crossed the forks will be sorted this week.